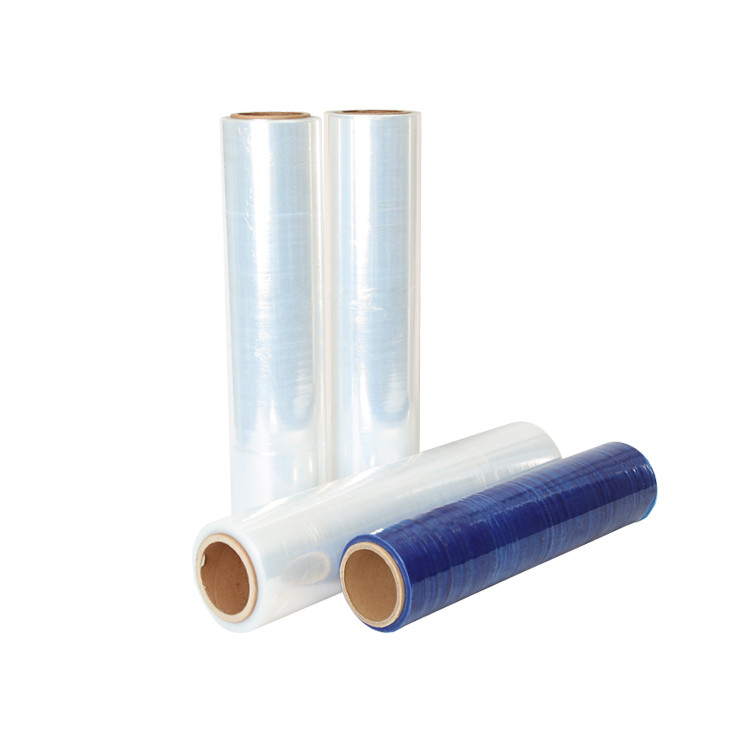

The production process of Stretch Film makes the stretch film itself have the characteristics of good self-viscosity, strong resistance to penetration, tear resistance, high transparency, good tensile properties and high shrinkage rate. How is the stretch film degreased? Specific methods and steps are as follows:

Before the formal use of stretch film equipment, all the parts that need to be used should be degreased, that is, the grease on the surface of the parts should be completely cleaned.

Stretch film generally uses degreasing agents to degrease, commonly used degreasing agents are dichloroethane, dichloroethylene, carbon tetrachloride, industrial ethanol and alkaline degreasing agents. Different occasions should choose different degreasing agent, in the use of degreasing agent to stretch film should pay attention to fire.

The process of stretching film degreasing is to scrape the grease on the surface of the parts and carefully remove the grease on the surface of the parts with degreaser. Then clean with cleaning agent, and then wash with cleaning oil; The degreased parts are finally blown dry with compressed air. Wear gloves during the whole work process and wash hands carefully after work.

Post time: Aug-21-2023